Paper Pouch for Food Packaging

As companies and consumers look for environmentally friendly substitutes for conventional plastic packaging, sustainable packaging solutions have become incredibly popular in recent years. The paper pouch for food packaging is one such creative solution. In addition to being eco-friendly, these pouches are multipurpose and efficient at maintaining the quality of food.

Paper Pouches: What Are They?

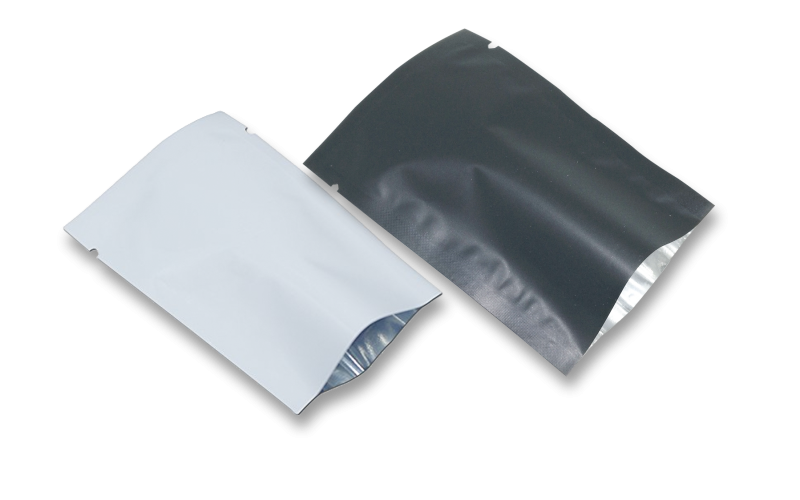

Paper Pouches or other biodegradable and composable materials are the main ingredients of paper pouches, which are flexible packaging options. They are made to minimize their negative effects on the environment while storing and safeguarding food. To increase durability and shield contents from moisture and air exposure, many paper pouches have extra layers or coatings, such as food-grade barriers or biodegradable laminates.

Advantages of Paper Pouches for Food Packaging

- Eco-Friendly: Paper pouches are a more environmentally friendly option than plastic packaging because they are biodegradable, compostable, and frequently recyclable.

- Versatile Use: These pouches can be used for a wide range of food items, such as baked goods, coffee, tea, snacks, and dry fruits.

- Customizable: To improve product presentation and consumer appeal, paper pouches can be printed with branding, nutritional data, and other information.

- Space-saving and lightweight Paper pouches are more space-efficient than rigid packaging, which lowers transportation expenses and the carbon footprint.

- Safe for Food Storage: Paper pouches with food-safe coatings successfully shield goods from impurities, moisture, and oil.

Various Types of Paper Pouches.

Flat Bottom Pouch- Products having a steady base for display are brown paper pouches.

Zippered Paper Pouches – Resealable zippers allow air to flow inside the pouch which keeps food fresh for a longer time.

Window Pouches – A transparent part allows the consumer to view the contents of the pouch.

Stand-Up Pouches- Highly favored packing systems for snacks and dry food due to consumer-friendly design.

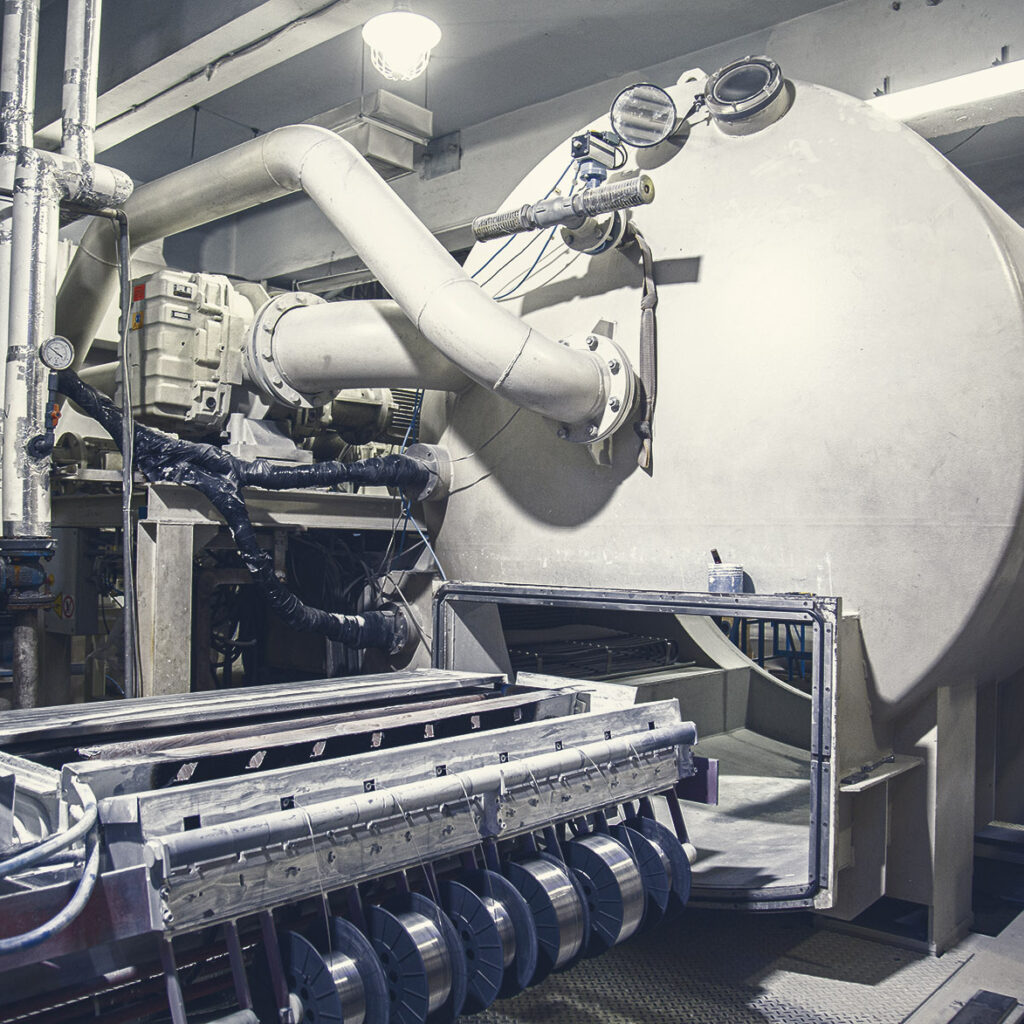

Sustainable Future of Paper Packaging

Demand for sustainable packaging keeps increasing as concern for environmental issues increases by consumers. Most companies that have studied the sustainability agenda are found to have taken part in pioneering paper pouches; thus, they become more committed to reducing plastic waste and advancing environmentally sustainable methods. Advances in technology additionally pave the way for durable and more functional paper-based packaging options, which would suit businesses’ initiatives in going green.

Towards reducing plastic waste in the environment and promoting sustainability, this step of converting food packaging into paper pouches would benefit very much. This innovative alternative, which is recyclable but durable and even customizable, could be a big step forward for environmentally responsible business and household practices. Investing in paper would not only save the earth, but also promote the brand image in this eco-conscious world.