METALLIZED FILM

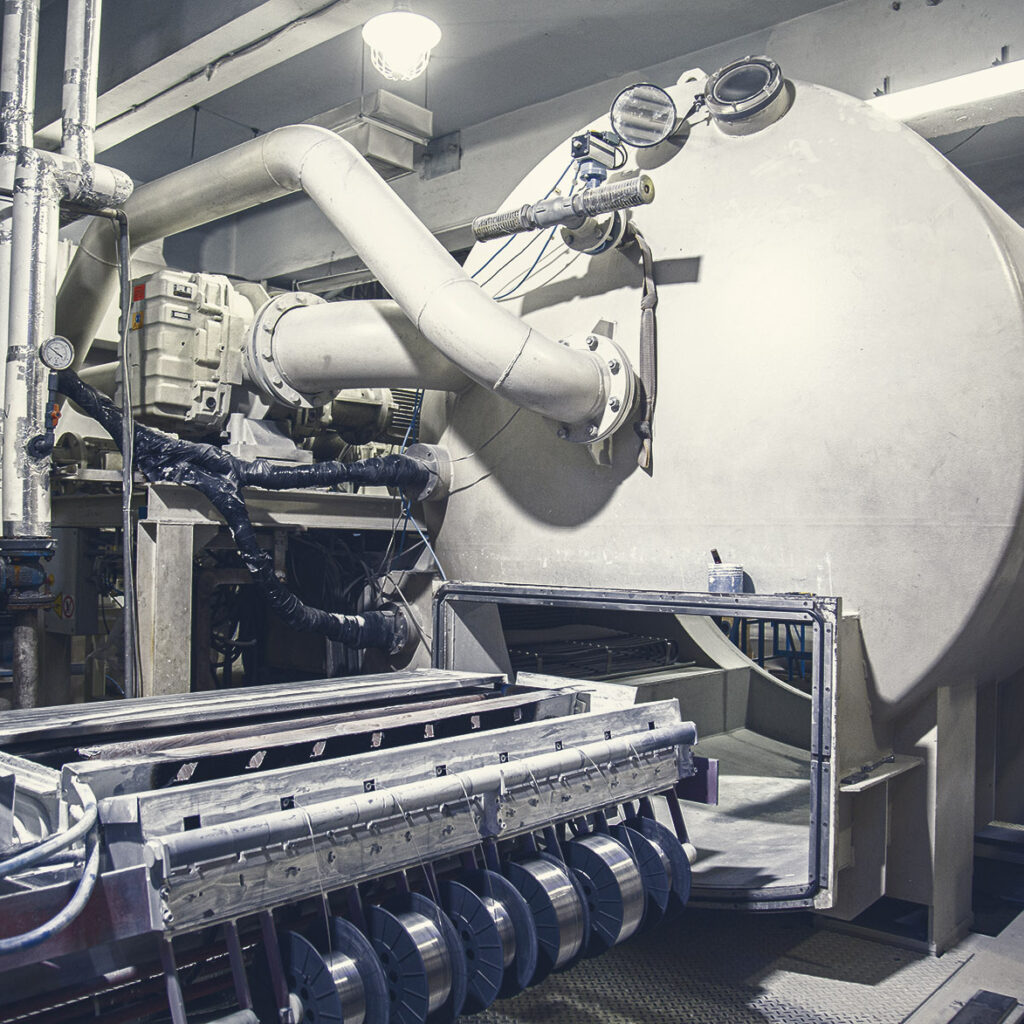

Metallized film is a type of plastic film that has a thin layer of metal deposited on its surface. This process is known as metallization and is achieved by using various techniques such as vacuum deposition, sputtering, and electroplating.

The metal layer on the film can be made from a range of materials such as aluminum, copper, and silver. The thickness of the metal layer can also vary depending on the application and requirements. The metal layer provides the film with unique properties such as high barrier properties, heat resistance, and a shiny appearance.

Application of Metallized Film:

Metallized films are widely used in various industries due to their unique properties. Some of the common applications of metallized films include:

- Packaging: Metallized films are extensively used in the packaging industry. They are commonly used in food packaging, pharmaceutical packaging, and cosmetic packaging. The metal layer on the film provides a high barrier to oxygen and moisture, which helps to increase the shelf life of the product. Metallized films are also used in flexible packaging, which is widely used in the food industry.

- Insulation: Metallized films are used as insulation in various industries. They are commonly used in the automotive industry as a heat shield. The metal layer on the film reflects the heat, which helps to keep the temperature inside the car stable.

- Labels: Metallized films are used in the labeling industry to create shiny and attractive labels. They are commonly used in the cosmetic industry to create high-end packaging.

- Solar Control: Metallized films are used in the construction industry as solar control films. They are commonly used in buildings to reduce the amount of heat and glare that enters the building. The metal layer on the film reflects the heat and light, which helps to keep the interior of the building cool.

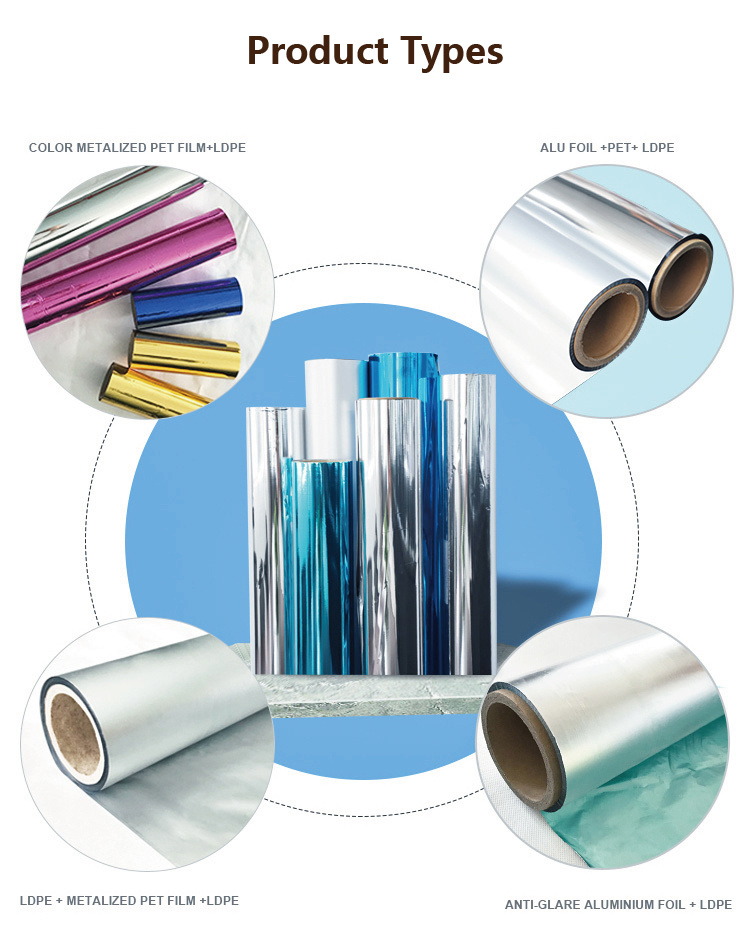

Types of Metallized Film:

Metallized films are available in different types depending on the application and requirements. Some of the common types of metallized films include:

- Vacuum Metallized Film: Vacuum metallized film is the most common type of metallized film. The process involves placing the plastic film in a vacuum chamber and then depositing a thin layer of metal on the surface. The metal layer provides high barrier properties and a shiny appearance to the film.

- Sputter Metallized Film: Sputter metallized film is created by using a sputtering process. The process involves bombarding the metal target with ions, which then deposit the metal onto the plastic film. Sputter metallized film provides better adhesion and durability than vacuum metallized film.

- E-beam Metallized Film: E-beam metallized film is created by using an electron beam to evaporate the metal target. The process provides better control over the thickness of the metal layer and creates a uniform layer of metal on the surface.

- Electroplated Metallized Film: Electroplated metallized film is created by using an electroplating process. The process involves immersing the plastic film in a solution containing the metal ions and then passing an electric current through the solution. The metal ions then deposit onto the surface of the film, creating a uniform layer of metal.

Advantages of Metallized Film:

Metallized films offer several advantages over other types of films. Some of the common advantages of metallized films include:

- High Barrier Properties: Metallized films provide high barrier properties to oxygen and moisture. This helps to increase the shelf life of the product.

- Heat Resistance: Metallized films are heat resistant, which makes them suitable for high-temperature applications.

- E-beam Metallized Film: E-beam metallized film is created by using an electron beam to evaporate the metal target. The process provides better control over the thickness of the metal layer and creates a uniform layer of metal on the surface.

- Shiny Appearance: Metallized films provide a shiny appearance, which makes them attractive for packaging and labeling.

- UV

OUR PRODUCTS

Metallized Polyester:

Metallized polyester is a type of plastic film that has a thin layer of metal deposited on its surface, typically aluminum.

This process, known as metallization, creates a reflective and shiny appearance that can be used for various applications, including packaging, printing, insulation, and decoration.

- Metallized polyester is commonly used in food packaging, particularly for snacks and confectionery, to enhance the visual appeal of the product and provide a barrier against oxygen, moisture, and light. It is also used

in printing for labels, posters, and stickers to create a metallic effect, and in insulation to reflect heat and reduce energy loss. - Metallized polyester has several advantages over other materials, including its low cost, lightweight, and

flexibility, making it easy to handle and process. It is also recyclable and has a high resistance to chemicals,

making it a preferred choice for various industrial and consumer applications.

Overall, metallized polyester is a versatile material with unique properties that make it suitable for a wide range of

applications, particularly where a shiny and reflective surface is desired.

Metatex Pvt Ltd provides the highest grades of metalized polyester for food packaging, decorative and textile weaving industries. Please contact us directly on our website or social media outlets for specific information or for requesting a price quotation.

Metallized Cast Polypropylene:

Metallized cast polypropylene (MCPP) is a plastic film commonly used in packaging applications. It is made by applying a thin layer of metal, typically aluminum, to a cast polypropylene substrate. This process creates a highly reflective and shiny surface that is ideal for enhancing the visual appeal of products and attracting consumer attention along with providing a visual barrier for light sensitive food items.

- MCPP offers several advantages over other packaging materials, including its excellent moisture barrier properties, which help to protect the contents from spoilage. It is also highly resistant to punctures and tears, making it ideal as a laminate for packaging products that require high levels of protection during shipping and handling.

The metallized cast polypropylene offered at Metatex pvt ltd is a premium and cost-effective packaging film that offers a range of benefits, including excellent barrier properties, high bond strength, low sealing and excellent machinability for your food packaging and lamination applications.

Add a Comment